Tensile Membrane Fabric Roofing

Synergy Prefab is a leading manufacturer and supplier of tensile membrane fabric roofing systems in Chennai. Our innovative designs are built to cover large open spaces using flexible, UV-resistant membranes stretched over engineered frameworks. These lightweight roofing solutions are ideal for commercial, institutional, and public applications that require both aesthetics and performance.

What is Tensile Membrane Fabric Roofing?

Tensile membrane roofing is an architectural roofing system made from PVC, PTFE, or PVDF-coated fabric stretched across a steel framework. It relies on tensile force instead of compression, resulting in:

Wider spans with fewer support columns

Natural light diffusion

Sleek, sculptural shapes

These roofs are commonly used in

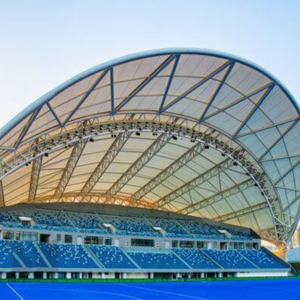

Sports stadiums and arenas

Outdoor event pavilions

Convention centers and exhibition halls

Walkways, atriums, and courtyards

Technical Specifications

1

Fabric Membrane Materials

PVC-coated polyester – cost-effective and UV-resistant

PTFE-coated fiberglass – non-stick, fire-resistant, long lifespan

ETFE films – self-cleaning, ultra-lightweight, excellent light transmission

2

Framework Options

Galvanized steel, MS, or stainless steel structures

Modular or fixed systems depending on span and usage

Wind-load and seismic-resistant anchoring systems

3

Design Capabilities

Forms: Cone, barrel vault, hyperbolic paraboloid, waveforms

Translucency levels: 15–65%, depending on material

Color options and printed branding available

Advantages of Tensile Fabric Roofing

Lightweight yet durable

reduces structural load

Custom shapes & aesthetics

perfect for signature architecture

Energy efficiency

reduces need for artificial lighting

Rapid installation

ideal for tight construction schedules

Long service life

membranes last 15–30+ years with minimal maintenance

Applications

Airport terminals and transit hubs

Open-air auditoriums and amphitheaters

Car parking shelters and commercial entrances

Industrial loading bays

Resort and hospitality venues

Why Choose Synergy Prefab?

Chennai-based fabrication with rapid delivery timelines

Fully in-house team for design, engineering, and installation

Structures designed for coastal climates and high UV exposure

Use of internationally certified membranes with warranties

Track record of successful projects across Tamil Nadu and India

Our product

Cone-Shaped Tensile Car Parking Structure

We offer a wide range of tensile car parking structures for both residential and commercial use, highly valued by our clients for their ease of installation and adaptability to various sizes, areas, and designs. Our offerings include a diverse selection of tensile car parking sheds, car shed coverings, and structures for bicycles and four-wheelers.

Tensile Membrane Framework

Tensile Membrane Framework refers to a flexible framework designed to handle only tensile forces, without any compression or bending. These structures are often used for roofing because they can economically and attractively span large distances.

Tensile Membrane Framework can be applied in various configurations, such as single, double, or triple layers. The material used is durable, highly transparent, and significantly lighter compared to glass structures.

FAQs

What is tensile membrane fabric roofing used for?

Tensile membrane fabric roofing is ideal for large-span roofing applications like stadiums, walkways, outdoor pavilions, exhibition halls, and commercial entrances. It combines structural efficiency with modern design, allowing natural light while offering weather protection.

What materials are used in tensile fabric roofs?

The primary materials include:

• PVC-coated polyester fabric – cost-effective, UV-resistant

• PTFE-coated fiberglass – flame-retardant, self-cleaning, long-lasting

• ETFE film – ultra-lightweight, highly translucent, and recyclable

Are tensile membrane roofs durable in Indian climates like Chennai?

Yes. Our membranes are designed to handle intense UV exposure, humidity, and monsoon conditions. They come with waterproofing and fire-retardant certifications, ensuring safety and longevity in coastal environments like Chennai.

How long does a tensile fabric roof last?

Tensile roofing can last 15 to 30 years, depending on the membrane type and environmental exposure. We provide warranties on both fabric and structural integrity.

Is tensile membrane roofing energy-efficient?

Yes. Tensile roofs allow natural daylight to pass through, reducing the need for artificial lighting and improving thermal performance, especially in commercial spaces.

Can these roofs be custom-shaped or branded?

Absolutely. We offer custom shapes like cone, dome, and hyperbolic forms and can print logos or branding onto the fabric for commercial installations.

What is the installation time for tensile roofing?

Depending on size and complexity, tensile roofing systems can be installed in 7–15 working days, with faster turnaround for standard configurations