PRE ENGINEERED BUILDING MANUFACTURERS IN CHENNAI

Synergy Prefab is one of the leading pre engineered building manufacturers in Chennai, delivering high-quality, durable, and cost-efficient steel building solutions for industrial, commercial, and institutional applications. Our PEB structures are engineered at the factory, transported, and assembled on-site, ensuring faster construction timelines and superior quality control. We use premium-grade raw materials, advanced manufacturing technology, and international engineering standards to produce PEB systems that withstand extreme climatic conditions, seismic loads, and heavy-duty industrial usage.

Key Advantages of Synergy Prefab PEB Structures

Strength & Durability

Engineered for high load-bearing capacity, seismic resistance, and long-term performance.

Cost-Effective

Low initial investment, reduced construction time, and minimal maintenance costs.

Customizable & Modular

Easily expandable, relocatable, and adaptable to future needs.

Sustainable & Recyclable

All steel components are 100% recyclable, supporting green building initiatives.

Aesthetic & Functional

Flexible design options to match architectural and operational requirements.

Fast Installation

Precision-engineered components ensure quick and error-free erection.

Applications of Pre Engineered Buildings

Our PEB solutions are ideal for:

Industrial Warehouses & Storage Facilities

Airports & Hangars

Logistics & Distribution Centers

Manufacturing Plants

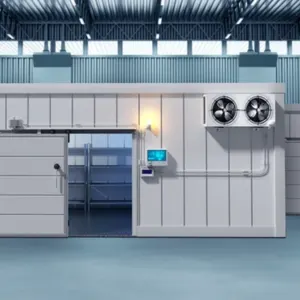

Cold Storage Units

Textile Processing Units

Fuel Station Canopies

Sports Halls & Stadiums

Multi-Level Car Parking Structures

Railway & Bus Terminal Shelters

PEB Components We Manufacture

1

Primary Frames

Built-up I-beams, trusses, and castellated beams.

2

Secondary Members

Cold-formed Z and C purlins.

3

Roof & Wall Panels

Profiled steel sheets, sandwich panels, and cladding.

4

Accessories

Mezzanine floors, bolts, fasteners, insulation materials, skylights, and ventilation systems.

Why Choose Synergy Prefab for PEB Projects?

End-to-End Turnkey Solutions

Design, fabrication, supply, and installation.

Adherence to International Standards

Ensuring safety, strength, and quality.

Experienced Engineering Team

Expertise in structural design and large-scale industrial projects.

On-Time Delivery

Proven track record of completing projects within schedule.

Frequently Asked Questions – Pre Engineered Buildings (PEB)

1. What is a Pre Engineered Building (PEB)?

A Pre Engineered Building is a steel structure fabricated in a factory and assembled on-site using bolted connections. It is designed to meet specific project requirements for load, size, location, and environmental conditions, making it faster, more economical, and more durable than conventional construction.

2. What are the benefits of choosing PEB over conventional buildings?

PEB structures offer faster construction timelines, lower costs, high durability, and flexibility for future expansion. They also require minimal maintenance, are eco-friendly due to recyclable steel components, and can be customized to any industrial, commercial, or institutional requirement.

3. How long does it take to construct a PEB in Chennai?

Construction timelines vary depending on project size and complexity. However, due to factory fabrication and pre-engineered precision, most PEB projects can be completed 30–50% faster than conventional buildings.

4. Can PEB structures withstand extreme weather conditions?

Yes. Synergy Prefab’s PEBs are designed to resist heavy wind loads, seismic activity, and extreme temperature variations, making them suitable for Chennai’s coastal climate and other challenging environments.

5. What industries commonly use PEB solutions?

PEB structures are widely used for warehouses, factories, cold storage units, logistics hubs, commercial showrooms, aircraft hangars, sports facilities, multi-level car parks, and institutional buildings.

6. Are Pre Engineered Buildings cost-effective in the long run?

Yes. The initial cost of a PEB is lower due to efficient material usage, reduced labor costs, and shorter construction periods. Additionally, their low maintenance requirements and long lifespan make them highly cost-effective over time.

7. Can I customize the design of my PEB?

Absolutely. Synergy Prefab provides complete design flexibility, including size, layout, cladding materials, roofing types, insulation, and color options to meet your operational and aesthetic needs.

8. Do PEBs comply with Indian building codes and safety standards?

All our PEB structures are designed and manufactured in compliance with IS codes, international engineering standards, and local building regulations, ensuring safety and structural integrity.

9. What is the typical lifespan of a PEB?

With proper maintenance, Synergy Prefab’s PEB structures can last 30–50 years, thanks to corrosion-resistant coatings, durable steel components, and weatherproof designs.

10. Do you offer installation services for PEBs in Chennai?

We provide end-to-end turnkey solutions, including design, fabrication, delivery, on-site erection, and after-sales support across Chennai and other parts of India.